JINGTENG WELDING MATERIAL

30 Years of Professional Production of Welding Consumables

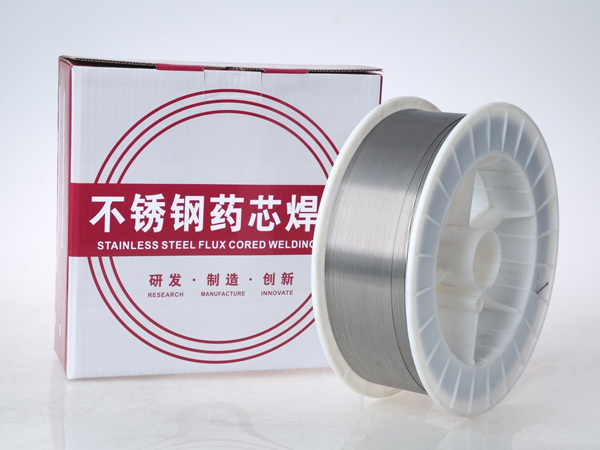

We Are One Of China's Leading Welding Material Manufacturing Companies, Specializing In The Production Of Welding Consumables Such As Welding Rods And Wires For 30 Years.

VIEW MORE