Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat:+86 13231948368

Email:Sales@Jingtengweld.Com

Tungsten carbide electrode

Category:

Product Introduction

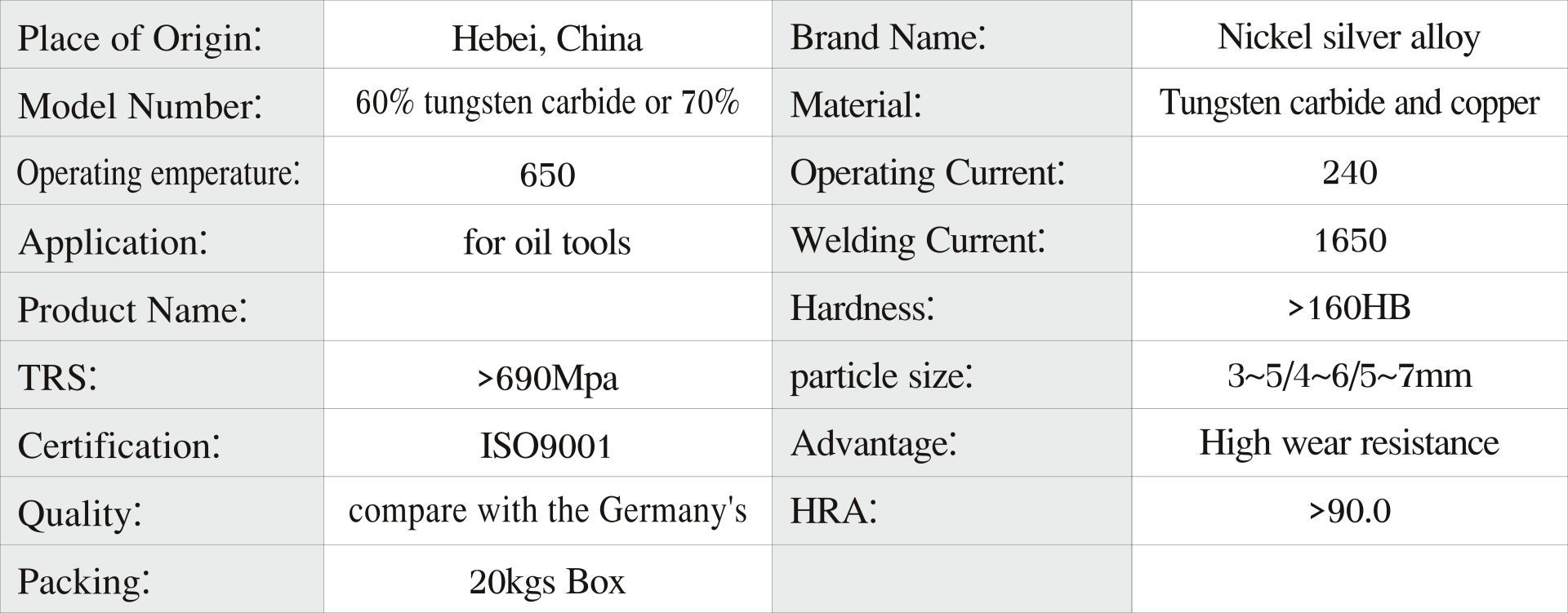

Quick details

Place of Origin: Hebei, China

Brand: JINGTENG

Model: tungsten carbide electrode

Diameter: 3 ~ 5 4 ~ 6 5 ~ 7 mm

Material: Copper-nickel alloy, tungsten carbide

Working temperature: standard temperature

Length: 300mm-500mm

Working current: DC AC

Application: Welding

Welding method: oxygen + acetylene welding

Product name: High quality tungsten carbide nickel copper electrode

Color: silver white

Application: Increase abrasion resistance and long service life

Applicable temperature: 1100 ~ 1300 degrees

Keywords: composite rod

Packaging and shipping

Sales unit: kg

Single package size: 33X24X16 cm

Single gross weight: 20.0 kg

Packing type: 5 kg / inner box; 4 boxes / carton; 25 boxes / wooden box

delivery time :

Quantity (kg) 1-200> 200

Eastern Time. Time (days) 5 to be negotiated

Product description

Description and application of tungsten carbide alloy:

Nickel-silver alloy and 60-70% tungsten carbide particles have excellent wetting properties. Our unique cemented carbide particles will provide the ultimate quality with excellent wear resistance and impact resistance in many cutting and abrasion and drilling applications. It can be found that this hardened rod is used in bulldozing equipment / tools, oil fields / mining, drilling / milling / boring / cutting tools, and many agricultural tools. Always make sure that the surface is free of oxides and clean before adding bronze flux. Use a neutral flame to heat the base material to about 1700F, apply flux using the end of the rod, and place carbide in the desired area. Pre-coating the surface with nickel silver may also help.

|

Tungsten carbide |

Ni |

Cr |

Fe |

Sn |

|

65% |

15.0 |

0.35 |

0.50 |

0.35 |

Standard sizes

|

Grade |

Size(mm) |

Particle(mm) |

Color |

|

YD-8 |

6 |

6~8 |

silver |

|

YD-5 |

5 |

4~6 |

silver |

|

YD-3 |

4 |

3~5 |

silver |

Application

It is mainly used for surfacing welding of some severely worn or cut workpieces in the petroleum, mining, coal mine, geology, construction and other industries, such as: milling cutters, grinding, centralizers, reamers, drill pipe joints, hydraulic cutters Scraper, planer, coring drill, pile drill, twist drill, etc.

Packaging and shipping

Most of the electrodes we have in stock.

If production is needed, depending on your quantity, the normal delivery time is 7-15 working days.

Contact information

We are a factory with 20 years of production experience, specializing in the production of various welding materials, especially wear-resistant welding materials, stainless steel welding materials, hard alloy rods, stainless steel electrodes, copper alloys, aluminum alloys, hard surface surfacing welding wires, etc.

If you have any questions, please feel free to contact me.

Shirley Zhang

Mobile: 0086-13231948368

Email: sales@jingtengweld.com

Address: New Materials Industrial Park, Qinghe County, Xingtai City, Hebei Province, China

Fax: 0086-0319-5396882

Application areas

Environmental protection machinery

Metallurgy

Medical devices

Petrochemical industry

Pressure vessel

Key words:

Online consultation